Applications

Overview

Visual Vent's database supports many different types of equipment. We add each product with a 3D model that shows vent and duct connections, along with other relevant details.

Users do not have to know technical product details to design a system. We can use sensitive data in the design process without exposing it to anyone.

The following list of products show typical design methods.

- Heating Appliances

- Generators

- Kitchen Hoods

- Pizza Ovens

- Energy Recovery

- Fans

- Dampers

- Barometric Dampers

- Filtration Devices

- Cleaning and Sanitation Devices

Heating Appliances

|

Design rules are tailored to the specific requirements of the appliance. Fuel input, CO2, temperatures and altitude to mention a few. The data is used to create precise operating data to be used in the vent calculation. The program will base the outcome on factors like pressure limits, allowed venting materials, fitting types and terminations. All combustion air requirements are included too. |

Generators

|

Exhaust volume and temperature will be used to generate calculation data for the exhaust system. This includes thermal expansion data based on requirments of the products used. The program will check if the system pressure exceeds the equipment limits. |

Kitchen Hoods

|

Air volume, temperature and hood pressure loss are the main starting parameters for the hood calculation. Other factors, such as balancing for multiple hoods are also considered. The software provides all system calculations, including duct loss, total fan volume, and static pressure requirements. |

Pizza Ovens

|

Exhaust air volume, fuel type and temperatures are the main parameters for pizza ovens. The software provides all system calculations, including total fan volume and static pressure requirements. |

Energy Recovery

|

Data from nearly any heat source can be used as starting point for the vent system and heat transfer calculation. Other factors, such as operation cycles and time can be used to generate more accurate energy recovery estimations. |

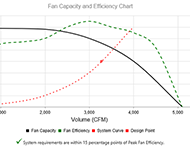

Fans

|

Air/gas volume, compositions, temperature and pressure requirements are the main parameters used. The software can factor in loss of capacity due to system conditions in proximity to the fan. Where applicable, the software can also determine if the total fan efficiency is within required range. |

Dampers

|

Volume limits, temperature limits, pressure limits, optimal operation area and dynamic losses at different settings can factored in. We can even provide a fixed damper setting where the desired pressure loss is known. |

Barometric Dampers

|

Our Barometric Damper calculation is considering all possible scenarios. Including spillage check, room air volume, resulting air/gas mixture and temperature. We can also trigger warnings based on design rules for both heating appliances and vent system. |

Filtration Devices

|

Pressure resistance at different air flows with both best and worst case condired for the system. Many other parameters can be considered. |

Cleaning and Sanitation

|

Application settings and duct velocities are important factors when selecting UV-C and Ozone systems. We provide that data based on the rest of the system calculation. |

Request More information

Questions, Comments, Pricing Inquiries, Live Demo Requests.